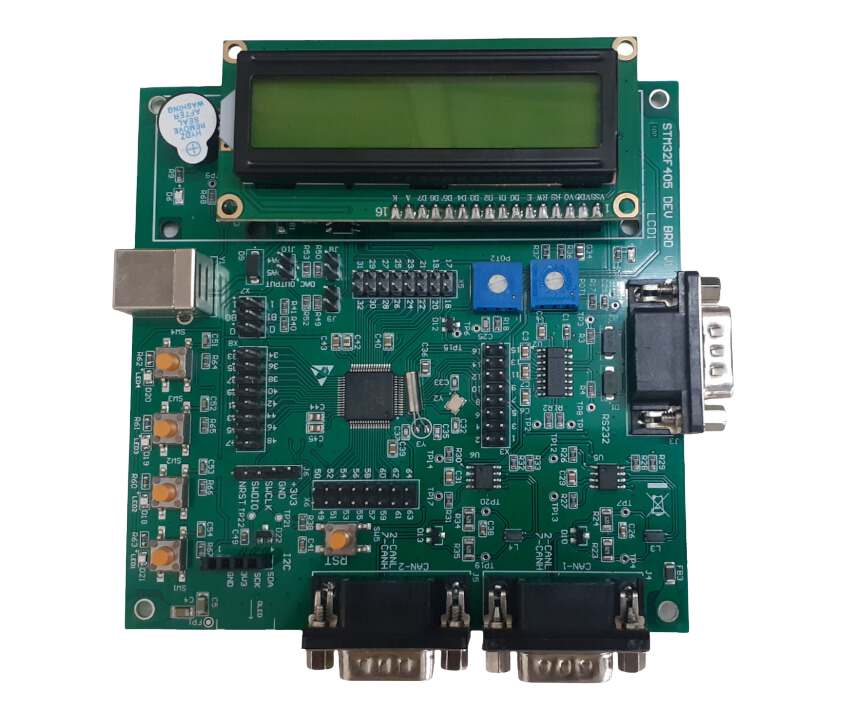

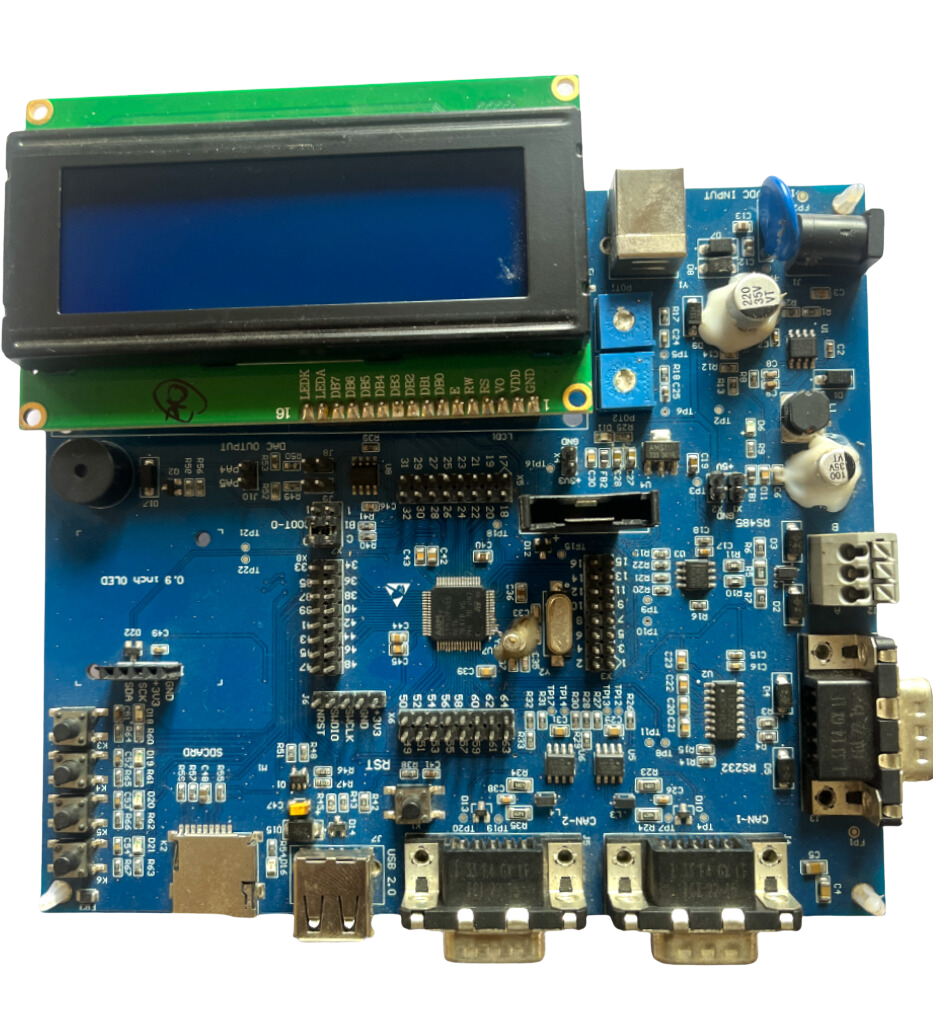

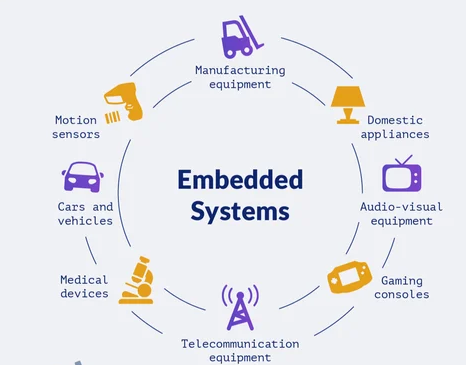

Transform Ideas to Complete Product

VAct Technologies helps transform ideas to finished product after understanding the application needs and application requirements of the customer. The team of designers gives shape to concepts keeping in mind factors such as functionality,practicability, reliability and aesthetics of the product